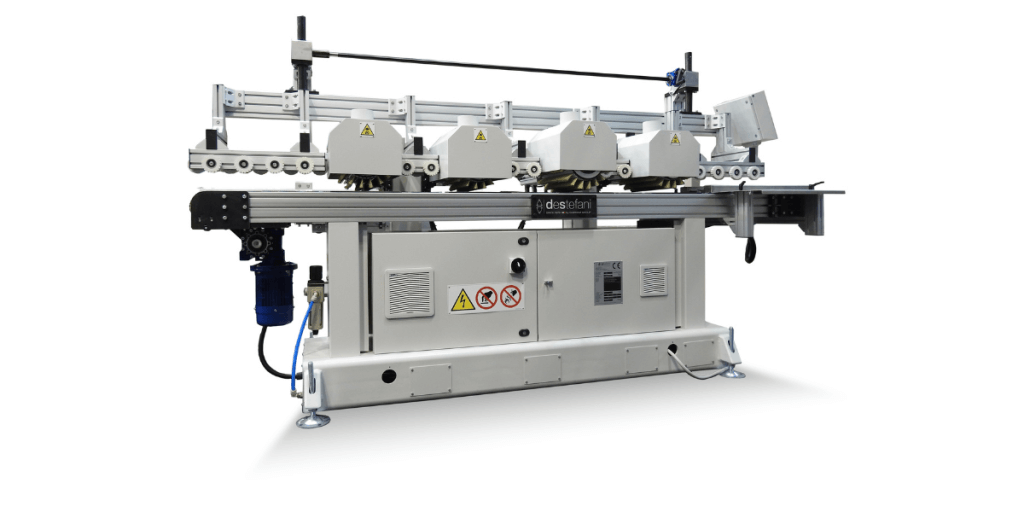

The MVS « Floor » is a sanding/brushing machine for floor elements, profiles and flat elements, equipped with four working units that can be

fitted with different types of grinding wheels and brushes for high-quality sanding, rusticating, smoothing or cleaning.

The work of the grinding wheel can be made even more effective by a system that oscillates the units.

It is the ideal solution for sanding the top surface of parquet and floor elements, frames, poles, strips, elements of door and window frames,

veneers, solid wood elements and unfinished and coated treated MDF parts.

THE FRAME

The MVS « Floor » is made of thick steel, designed to compensate vibrations and guarantee perfect stability even during the more demanding work phases. The base has a fixed entrance and the units are aligne on the right hand side of the belt support beam.

CONVEYOR SYSTEM

The parts run correctly on a large (320 mm) rubber conveyor belt with three internal canvas tracks and a rough running belt, with a rubber cover.

The upper press – with a double row of rubber wheels with ball bearings – can be positioned vertically according to the thickness of the elements

being processed.

The infeed part counter has a reference square with adjustable width.

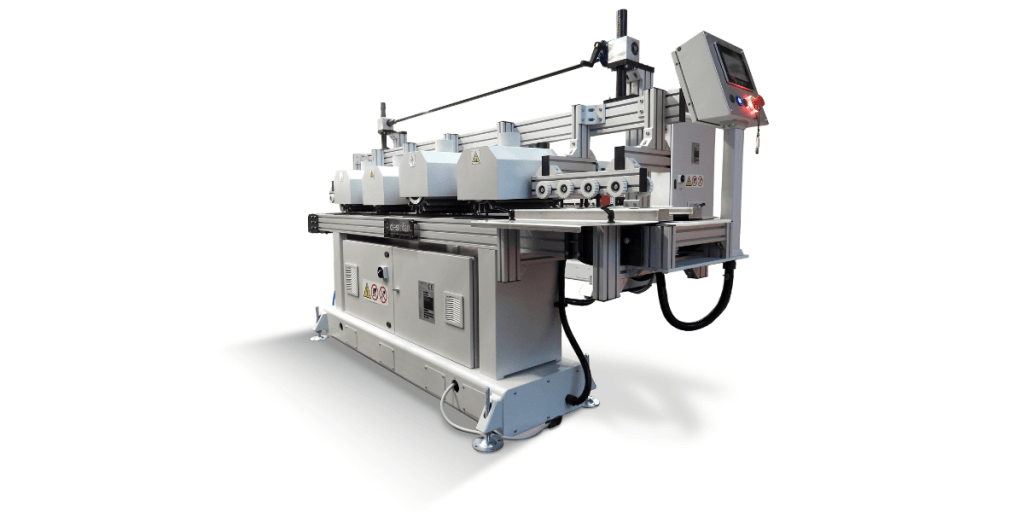

CONTROL SYSTEMS

The control panel is used to manage all working units and every function of the MVS « Floor » with its electronic programmer and 9.7 inch touch screen disp lay. It provides immediate viewing and programming of the conveyor system speed (feed rate in m/min), alarm diagnostics, language selection, workpiece count with the possibility of calculating how many metres have been sanded/brushed rather than the total number of working hours. Electronic system for adjusting the intervention times of the various units installed on the machine, based on the feed speed.

For each unit the inclusion or exclusion of the (optional) brush oscillation system, the cutting speed of the abrasive wheels/brushes and the direction of rotation (clockwise oranti-clockwise) can all be managed.

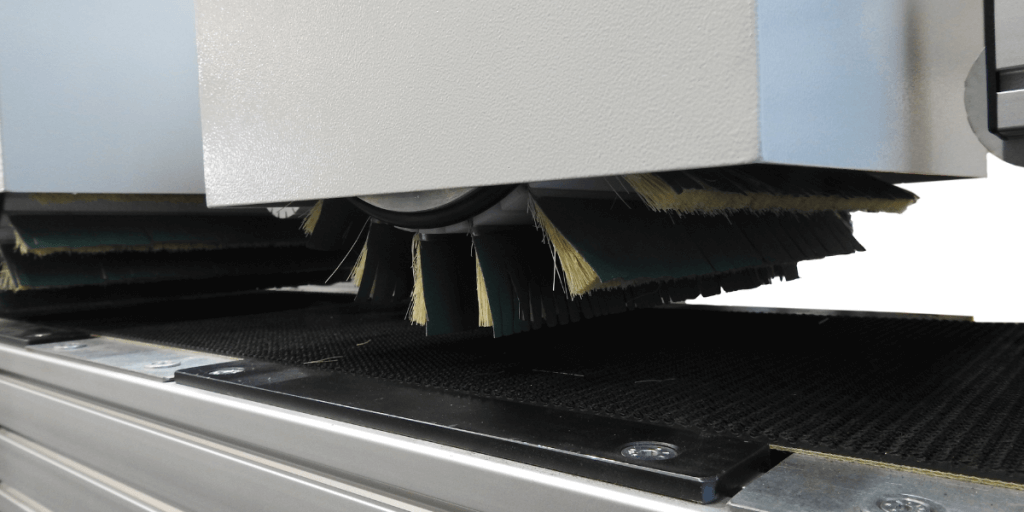

ABRASIVE WHEEL BRUSHING UNIT MOD, « SB 300 »

The MVS « Floor » is equipped with four units fitted with abrasive brushes mounted on slides and crosses for vertical positioning according to the thickness being processed. The adjustment axis is manual with mechanical digital position reader and axis adjustment screw with double thrust needle bearing.

The protective cap houses the dust suction port.

The units can be fitted with different types of brushes to achieve different finishes:

sanding (Scotch Brite brushes, mixed paper or canvas or polyurethane resin flap brushes);

rusticating (steel or « Tynex » brushes);

smoothing (horsehair brushes);

cleaning (« Tampico » brushes).

An efficient suction system conveys dust and processing waste into a main duct for connection to the external vacuum cleaner.

MACHINE TECHNICAL FEATURES

Min/max part width: 50-300mm.m

Min/max part length: 600-3,000mm

Min/max part thickness: 15-60mm

Processing speed (adjustable with inverter): from 5 to 25m/min

Conveyor motor power: 1,5kW

AGGREGATE TECHNICAL FEATURES

“SB300”

Motor power: 2.25kW

Wheel size: 200x300mm

Suction port size: 100mm

Wheel rotation speed: between 420 and 1,720rpm

Wheel shaft: 30mm

Spindle-grinding wheel connection flange: 76mm

Angular adjustment: from -90 to +90 degrees