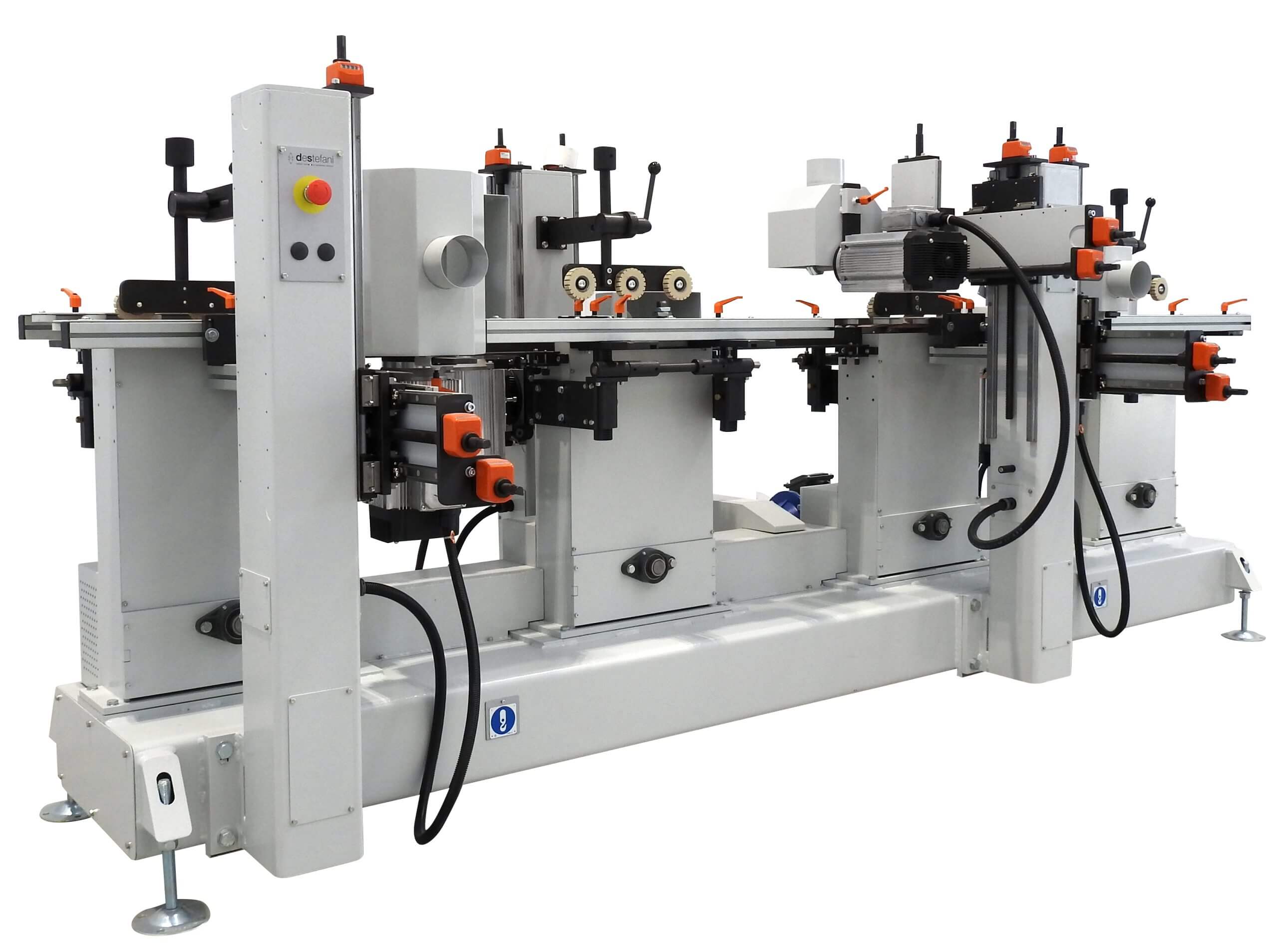

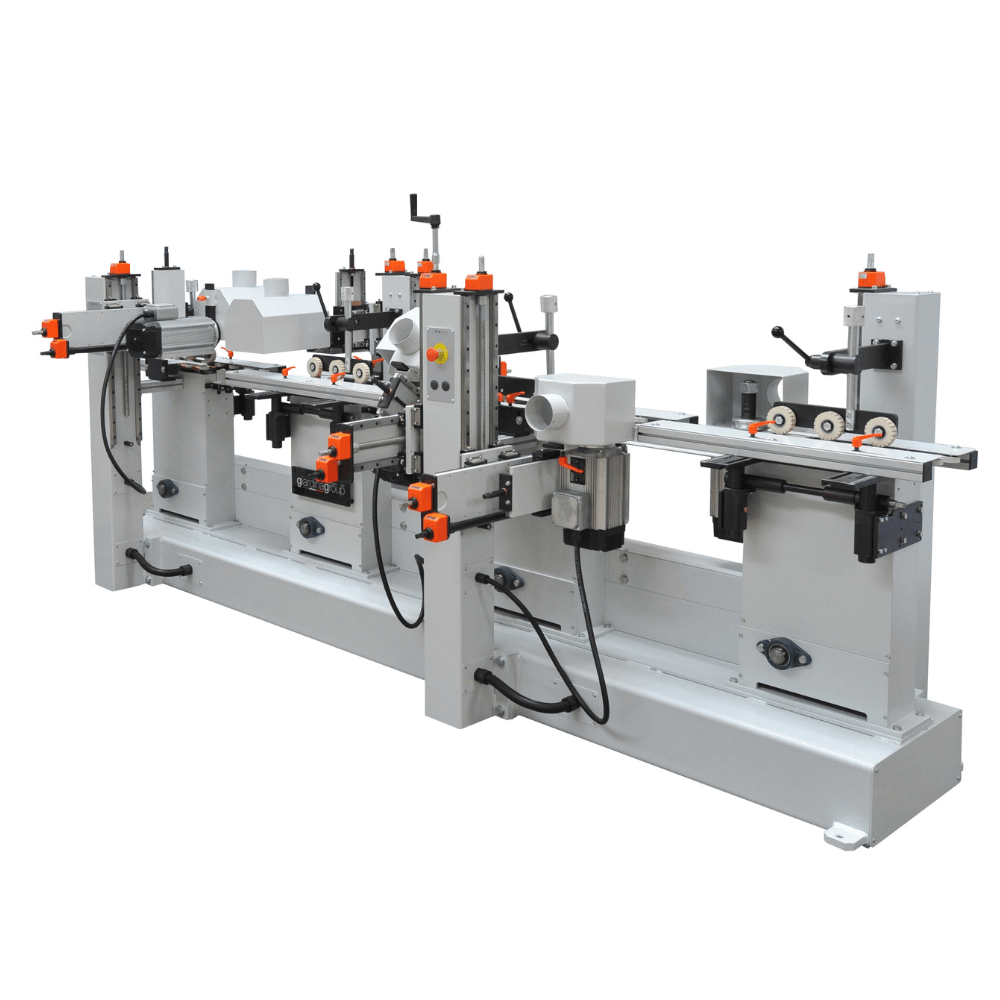

Model “MVS 3500 (LVGS 6SB800)” is a profile sander in the “MVS” series designed to sand frames, rods, moldings, window frames, veneered, solid wood and raw or coated MDF (coated with paint, polyurethane base coats, polyester or other coatings).

Model “MVS 3500 (LVGS 6SB800)” is fitted with a thick steel frame, designed to compensate vibrations and guarantee perfect stability even during the more demanding work phases. The fixed base is 3.3 meter long and the work aggregates are aligned on the right or left hand side of the belt modules. The support feet allow the work height adjustment. Moreover, the “MVS 3500 (LVGS 6SB800)” is designed to sand all four sides of the profile.

THE AGGREGATES

“MVS 3500 (LVGS 6SB800)” is fitted with six wheel sanding units of the Scotch Brite (“SB”) type, abrasive wheels for finishing, denibbing and brushing the sanded surfaces: four “SB100” aggregates operate on the profile side (side units with a useful thickness range up to 100 millimeters and 1.5 kW motor), the two “SB300” aggregates operate in a useful range up to 300 millimeters with their 2.2 kW motor. The six aggregates are tiltable up to 180 degrees (side and top operation).

With its flexible set-up, model “MVS 3500 (LVGS 6SB800)” can process parts with a minimum length of 800 millimeters and up to 300 millimeters in width, with a thickness up to 80 millimeters, and it offers high quality results in a contained timeframe.

CONVEYOR SYSTEM

The parts run on four 120 mm rectified rubber belts with central guide, activated by a cardanic drive with elastic compensating joints. The drive motor (1.5 kW) sits in a central position; the speed can be electronically adjusted via frequency drive. The side guides are bars with idle rubber rollers adjustable in width and thickness (rack system).

MACHINE TECHNICAL FEATURES

Workable sides: 4

Minimum part length: 800mm

Maximum part width: 300mm

Maximum part thickness: 80mm

Number of conveyor belts: 4

Number of sanding wheels per slot: 2

Processing speed: from 10 to 40m/min

Conveyor motor power: 1.5kW

Worktop height: 900mm

Total installed power: 12kW

Voltage: 400V

Machine length: 3,330mm

Machine width: 1,750mm

Machine height: 1,500mm

Part infeed-outfeed: manual

AGGREGATE TECHNICAL FEATURES

“SB100”

Motor power: 1.5kW

Wheel size: 200x100mm

Suction port size: 100mm

Wheel rotation speed: between 420 and 1,720rpm

Wheel shaft: 30mm

Spindle-sanding wheel connection flange: 76mm

Angular adjustment: from -90 to +90 degrees

“SB300”

Motor power: 2.25kW

Wheel size: 200x300mm

Suction port size: 100mm

Wheel rotation speed: between 420 and 1,720rpm

Wheel shaft: 30mm

Spindle-grinding wheel connection flange: 76mm

Angular adjustment: from -90 to +90 degrees

AVAILABLE ACCESSORIES

Electropneumatic system with timed intervention on infeed and outfeed of the sanding aggregate, manageable from the touchscreen panel.

Bi-directional Electronic recovery system to compensate for the sanding wheel wear, controlled by the programmable logic, to compensate wear in all operating positions.

Pneumatic blower to clean the parts with housing and spinning blowers with timed intervention inside.

“Industry 4.0” Set up.

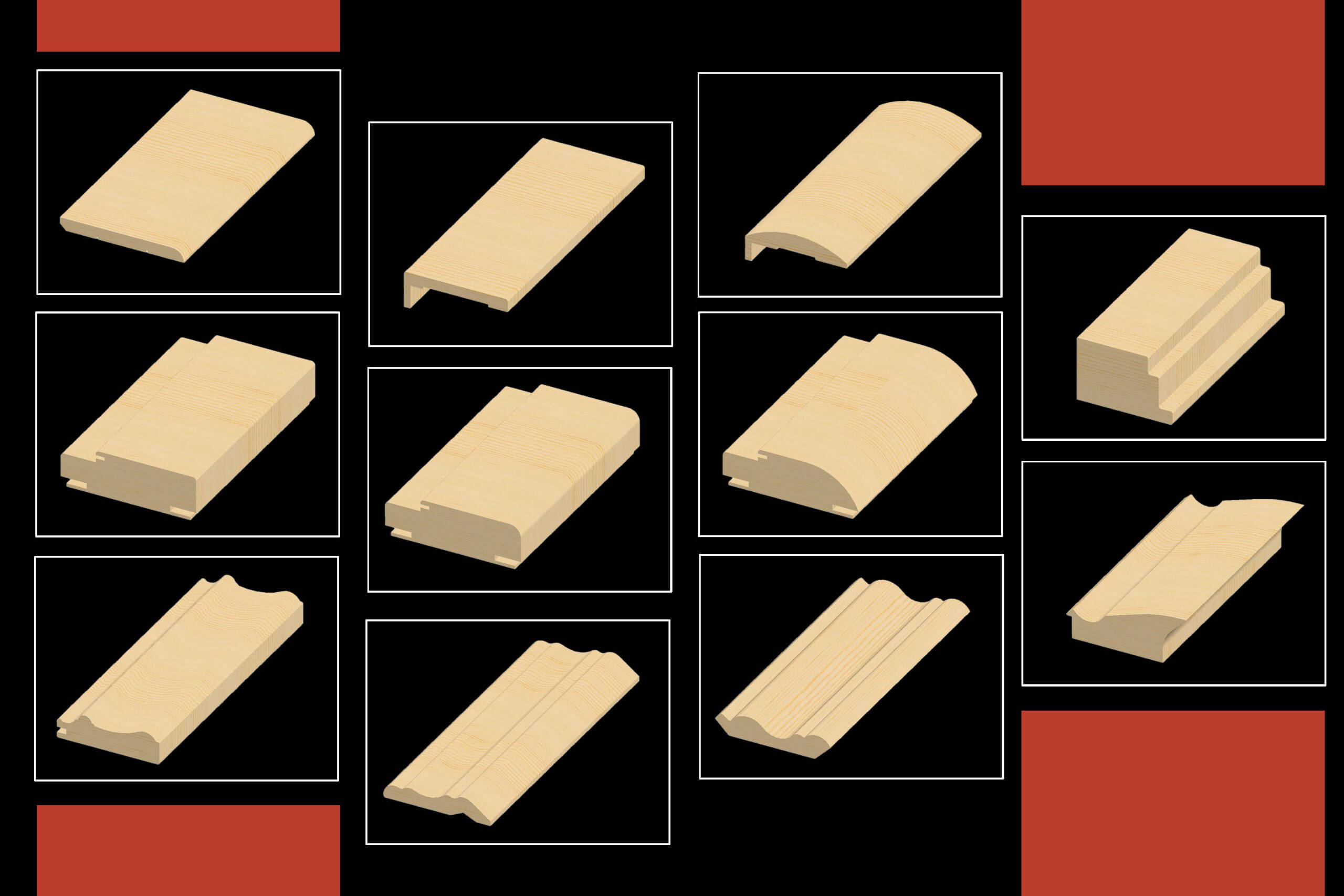

PROFILES

“MVS 3500 (LVGS 6SB800)” can process the following types of profiles: