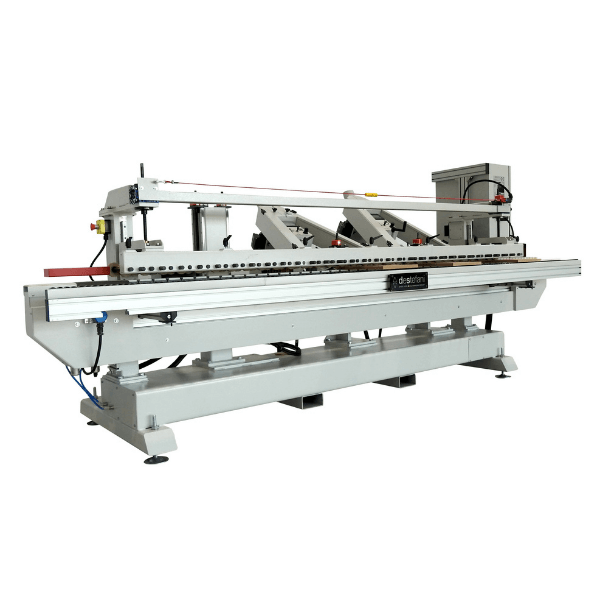

Model “MVT 2000 (LVGT 2AT1SB)” is an automatic single-side edge sander in the “MVT” series, perfect for sanding MDF and chipboard panel edges coated with PU base or water-base products. This machine is designed to process kitchen doors, interior and external doors and many other furniture products.

THE AGGREGATES

“MVT 2000 (LVGT 2AT1SB)” is equipped with two “AT” and one “SB100” unit. The belt sanding units “AT” are suitable for sanding straight and molded edges. They are 110 millimeters thick, with adjustable angle and interchangeable pad, to allow for the utmost possible flexibility and perfect sanding in a contained time frame to optimize the production cycle.

The Scotch Brite (“SB100”) aggregate is an abrasive wheels for superfinishing, denibbing and brushing the sanded surfaces. The “SB100” aggregate operates on a useful thickness up to 100 millimeters with its 1.5 kW motor.

The machine has a “PLC” (“Programmable Logic Controller”) as a general automation control unit and a dedicated “PLC” on each individual unit.

Model “MVT 3000 (LVGT 2AT2SB)” is a variant of “MVT 2000 (LVGT 2AT1SB)”, with two Scotch Brite “SB100” aggregates. Owing to the additional “SB100” unit, the sanding is even more effective on the first run.

FRAME AND CONVEYOR

“MVT 2000 (LVGT 2AT1SB)” consists of a thick steel frame, designed to compensate vibrations and guarantee perfect stability even during the more demanding work phases.

The side guide keeps the part straight while running in the machine on a track – which runs on two interchangeable steel guides – with a steel chain, on which the pads covered in high-resistance rubber 80 mm wide are fixed. The motor power is 1.1 kW and the part running speed – electronically adjustable with inverter – can be set from 5 up to 25 meters per minute.

MACHINE TECHNICAL FEATURES “MVT 2000 (LVGT 2AT1SB)”

Workable sides: 1

Minimum part length: 200mm

Minimum part width: 50mm

Maximum part thickness: 100mm

Processing speed: from 5 to 25m/min

Conveyor motor power: 1.1kW

Worktop height: 900mm

Total installed power: 7 kW

Voltage: 400V

Machine length: 3,400mm

Machine width: 1.700mm

Machine height: 1.500mm

Part infeed-outfeed: manual

MACHINE TECHNICAL FEATURES “MVT 3000 (LVGT 2AT2SB)”

Workable sides: 1

Minimum part length: 200mm

Minimum part width: 50mm

Maximum part thickness: 100mm

Processing speed: from 5 to 25m/min

Conveyor motor power: 1.5kW

Worktop height: 900mm

Total installed power: 9 kW

Voltage: 400V

Machine length: 4,400mm

Machine width: 1,700mm

Machine height: 1,500mm

Part infeed-outfeed: manual

AGGREGATE TECHNICAL FEATURES

“AT 110”

Motor power: 2.2kW

Variable belt rotation speed: 0,5 to 11 m/s

Sanding belt oscillation motor: 35 W

Adjustable work angle: from -10 to +90 degrees

Pulley thickness: 110 mm

Sanding belt maximum size: 2,800 x 110h mm

“SB100”

Motor power: 1.5kW

Wheel size: 200x100mm

Suction port size: 100mm

Wheel rotation speed: between 420 and 1,720rpm

Wheel shaft: 30mm

Spindle-sanding wheel connection flange: 76mm

Adjustable work angle: from 0 to +90 degrees

AVAILABLE ACCESSORIES

Electropneumatic system with timed intervention on infeed and outfeed of the sanding aggregate, manageable from the touchscreen panel.

Bi-directional Electronic recovery system to compensate for the sanding wheel wear, controlled by the programmable logic, to compensate wear in all operating positions.

Pneumatic blower to clean the parts with housing and spinning blowers with timed intervention inside.

“Industry 4.0” Set up.

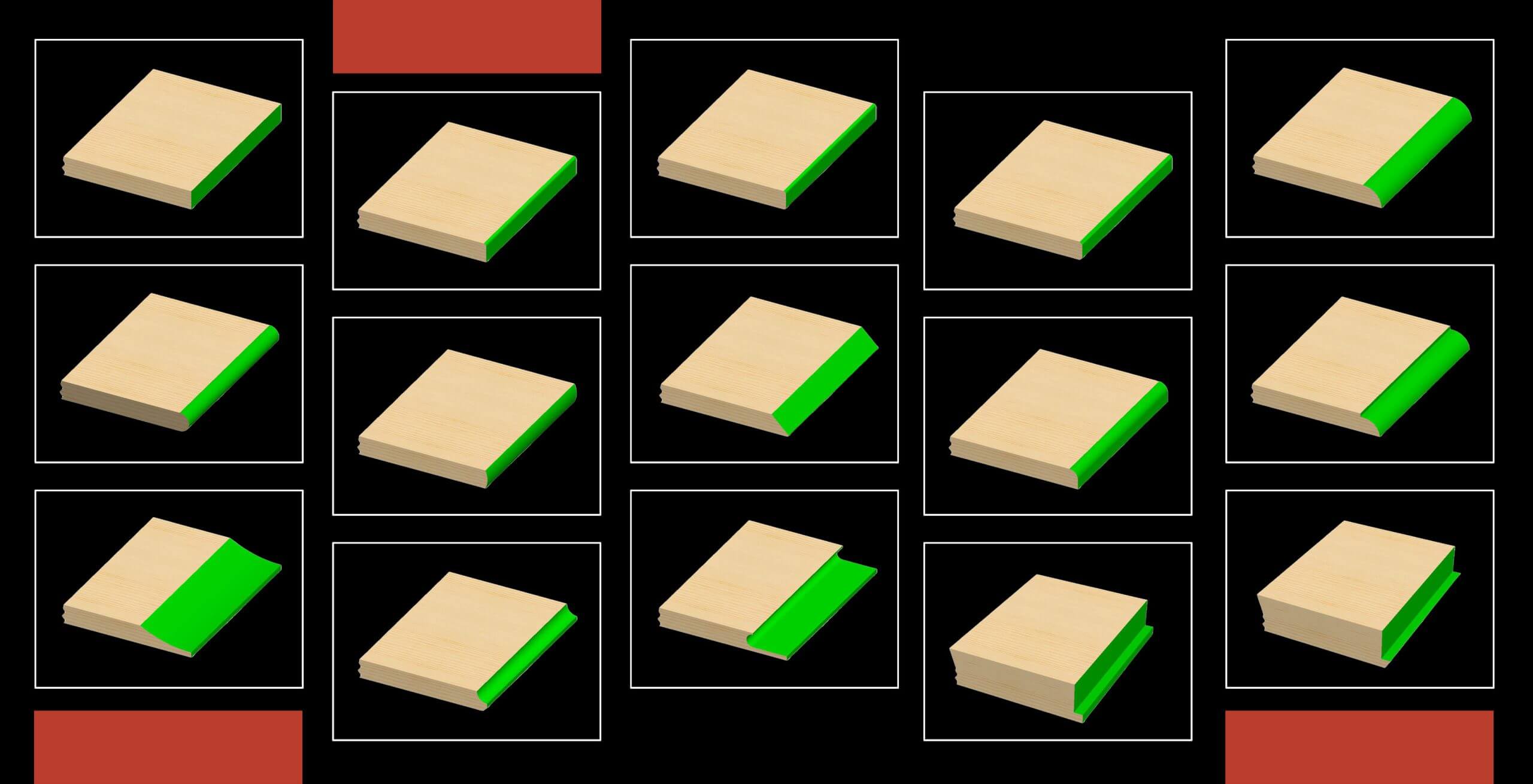

EDGES

“MVT 2000 (LVGT 2AT1SB)” and “MVT 2000 (LVGT 2AT2SB)” can process the following types of edges:

Want to see the “Destefani MVT” in operation? Click here.